STRIKER TANK CLEANING ROV

Remote crude oil non-man entry tank cleaning, at last, a remote tank cleaning crawler that actually works. ” THE STRIKER” makes it happen.

The STRIKER SUPER CRAWLER is for crude oil remote tank cleaning up to 110m (330 feet) diameter. This is not to be confused with the many Tonka type toys out there that look good. They may look good but, put them in a crude tank with 50 or more centimetres of heavy crude sludge. Then hook up with a vacuum hose full of sludge behind it. Now let us see how far the distance is that it can go inside the crude oil tank. How far can it go before stalling or tying itself in a knot around the roof legs.

Great toys for your kids. For a man’s business of crude oil tank cleaning, you need to get the job done. You need the real deal with the STRIKER SUPER TANK CLEANING CRAWLER. The writer has tried all these systems and variations over more than 25 years and knows well what works and what does not work.

Learning the lessons that these systems do not work in crude tanks unless the tank is virtually empty. Even with an empty tank the age-old problem of getting the ROV umbilical tied in knots around the roof legs means that men have to then go into the tank to undo the problem. Of course, this defeats the saying “non man entry”.

So with the STRIKER ROV this problem is solved and many other problems that other ROVs have.

The STRIKER enters a tank in one piece through a 24-inch manway via a special insertion ramp.

The STRIKER has a variable geometry track base that enters a tank in the closed position.

Once inside a tank, the operator activates the opening of the track base so the ROV is now a very stable platform that will not tip over as many of the other ROVs do and which then requires men to go inside the tank to rectify the problem.

The operator raises the super cannon together with its camera and light assemblies into its working position.

The STRIKER super cannon together with the camera and light assembly has rotational plus raise and lower direction movements.

Once inside the tank the operator can drive the STRIKER to the tank center. If there is a deep level of sludge the operator uses the cannon to fluidize this and cut a pathway through the sludge to the tank center. A hydraulic powered sludge pump is put inside the tank man way or connected directly to a draw off point to evacuate the liquidized sludge.

From the centre of the tank, the operator can direct the cannon jet using it to fluidize the sludge that will then flow to the hydraulic sludge pump. Because of the rotation of the cannon camera and light assembly, the STRIKER remains basically in the same place during the fluidization. This is possible with 270 degrees rotation and 170 degrees up/down of the cannon assembly. This also avoids the risk of getting the STRIKER umbilical tied in a loop or knot around the roof legs driving around in a tank.

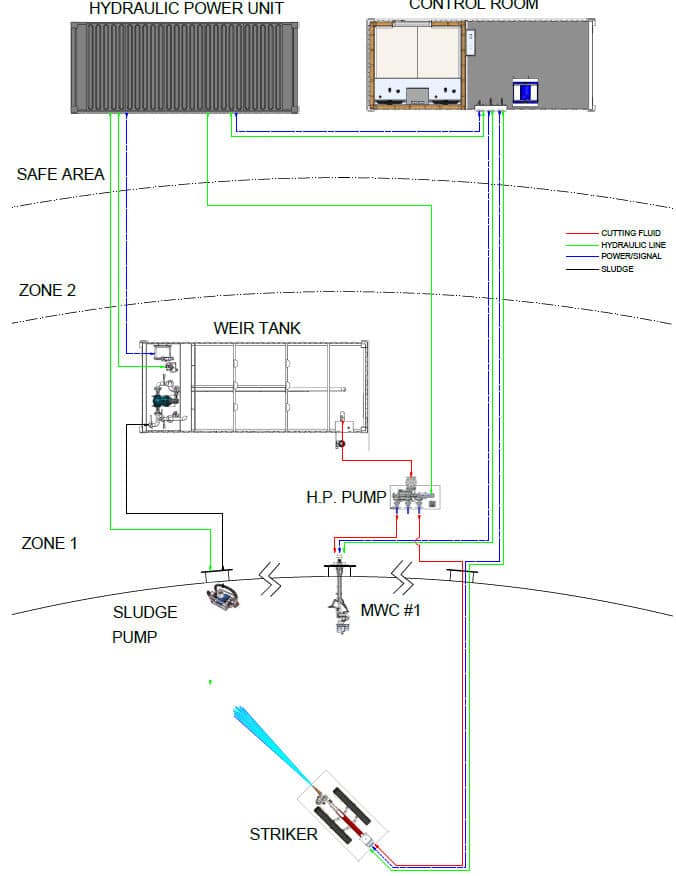

Ideally the STRIKER is used with the SUPER MANWAY CANNON tank cleaning system. The power hydraulic and 12v electric are all supplied by the HPU unit. The pressure for the STRIKER Cannon is supplied by the hydraulic powered pressure pump. The sludge pump for evacuating the liquidized sludge is also hydraulic powered by the HPU. All stop/start and speed of the pumps is controlled by the operator in the control room so pressures and flows can be adjusted to suit conditions inside the tank.

GAS or Oxygen monitoring of the tank being cleaned is via the detectors placed on a manway cannon unit fixed to a tank manway. This also gives the operator a second overview of the ROVs location inside a tank. The gas and oxygen system will shut down the system in the case of the gas or oxygen level exceeding the set limit and will not allow further operation until the level has been adjusted.

The liquidized sludge is pumped to the SUPER MANWAY CANNON Weir tank for primary separation of heavy solids and final filtration of the liquid before it is re-cycled through the pressure pump and through the cannon. The Weir tank is fitted with gas and oxygen detection, high and low level alarms and the on board lobe pump is also controlled by the operator and power is supplied from the HPU unit.

If you want a machine that works get it designed and made by an experienced tank cleaner. That is who we are, and we know what it is really like inside a crude oil tank and the conditions that need to be dealt with. Sucess is knowledge and experience in the tank cleaning field.

For more information email tony.strikerhydralink@tutanota.com